services and capabilities

CUT-TO-LENGTH

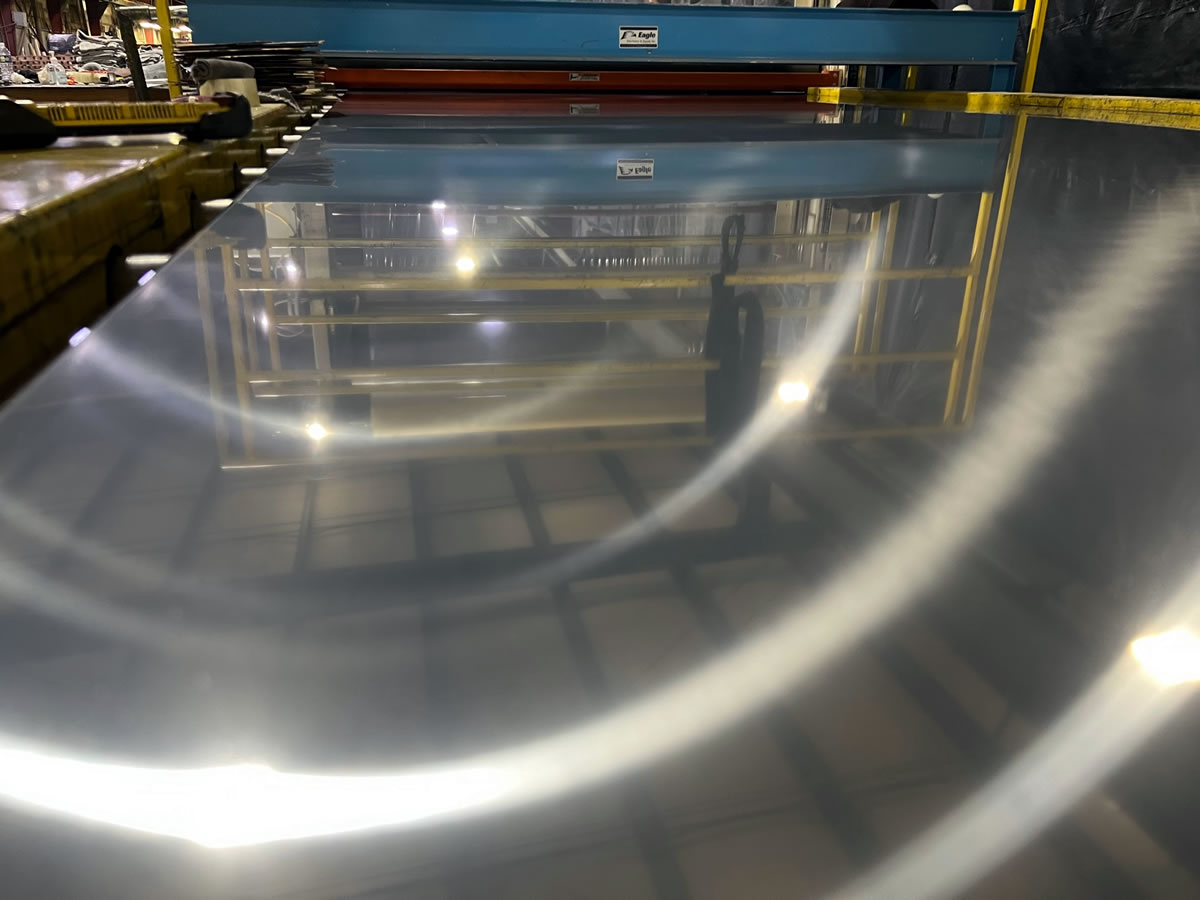

96” Stretcher-Leveler Cut-to-Length

- Eliminate or significantly reduce quality defects and a wide variety of coil variances.

- Ability to Obtain a level of flatness, camber correction and sheet stress relief that is not achievable by roll leveling.

- Stretch levelers can make shape improvements by up to 3000 I units.

Our unique stretcher line eliminates internal sheet stresses that cause spring-back, so shearing, punching, laser cutting, forming, and welding sheet is much easier. Our unique stretching sequence also eliminates coil quality defects including camber, arbor breaks, oil canning, edge wave, and centerbuckle.

72” Roller-Leveler Cut-to-Length

- Optional dual levelers, including 6-high Herr-Voss precision roller leveler.

- Roller levelers can improve shape form by 150/200 I units.

- 6 high Herr-Voss precision roller leveler eliminates back up roll marks on both top and bottom of material that a 4 high leveler will introduce into material. This is critical on surface sensitive material.

PRECISION LEVELING

- Sheet, plate & part leveling

- Reduce Material Stress: Equipment will flatten and relieve stress to eliminate "pop or spring back" when cutting. Ideal for leveling laser-cut, punched and plasma-cut parts.

- Able to reduce or eliminate crossbow in certain size material that other flattening processes can’t. By slightly angling the plate it will be fed through the machine and worked as if it were removing downbow instead of crossbow.

- Saves on time and cost: Fabricating and working with material that is not flat is very difficult and time consuming. Flattening the material prior to these other processes ensures less scrap and more throughput.

SHEARING

- PART OR SHEET OFFLINE SHEARING Aluminum & Stainless Steel up to 0.312”

- Part or sheet, offline shearing

- Cincinnati 120” Hydraulic Shear

- Ability to adjust rake angle on the fly drastically minimizes bow in cut pieces. Most shears leave a warped or bowed cut piece. This is more prominent the thinner the strips are. Having the ability to reduce the rake angle spreads the force over a much greater area thereby reducing the warpage or bow that is usually characterized by the shearing process.

BUFFING

- Our buffing lines can accommodate widths up to 96˝ and lengths up to 480˝. With state-of-the-art controls and custom-built buffing heads and versatility, our lines ensure optimum buff finish and consistency.

SLITTING

- Coil edge trimming

- Coil slitter w/ in-line roller leveler

- Coil break down

Materials We Work With

AUP works with both ferrous and non-ferrous metals. We offer leveling and correction services of primary and secondary metals. Our high standard of quality ensures customer satisfaction.

AUP offers roller leveling and stretch leveling for both aluminum and stainless-steel coils. Our roller leveling machines are capable of leveling coils up to 72”. Our stretch leveling machines can level coils up to 96”. Additionally, AUP offers precision leveling and buffing services.

Fast Free Quotes

Contact our team today for your free quote. Please complete our contact form or call us directly at (330) 535-3000 AUP provides consultation that ensures we understand the needs of your specific project. We provide you with a quote that promises to be precise and clear.

Packaging

- Full Stencilling Capabilities

- Interleave Paper

- PVC Application

- Custom Built Skids

- Other (by inquiry)

Download Our Brochure